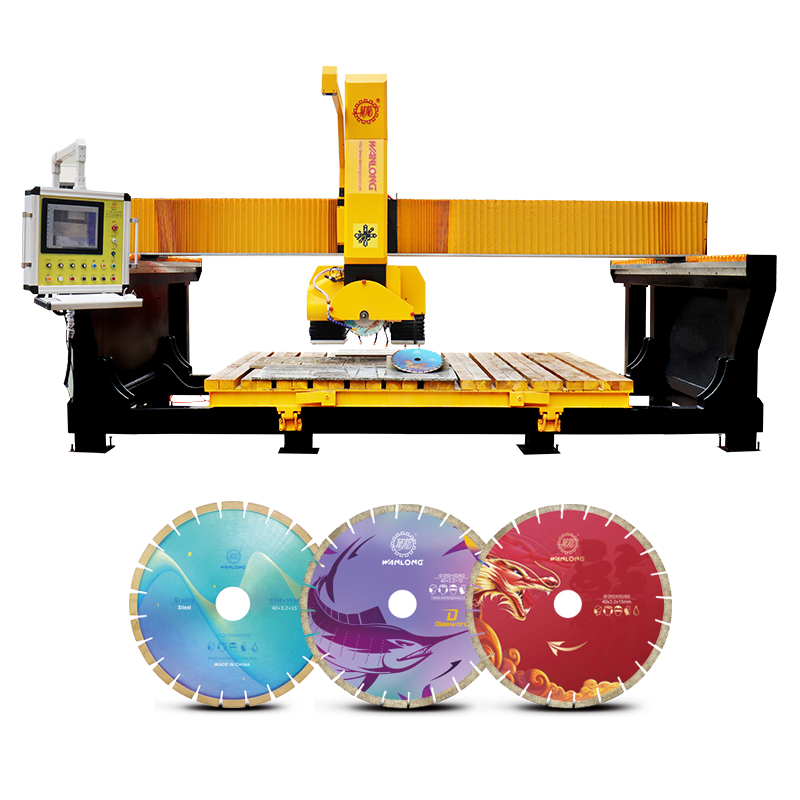

(CNC-5 鉑金) 5 軸數控橋式切割銑床

1. Italian 5 axis CNC control system, CAD, CAM drawing software and the digital servo motor

2 .5 axis interpolated

3 .Take photos and position, optimize typesetting that improve the material yield, and the suction cup automatically moves the workpiece to optimize the processing

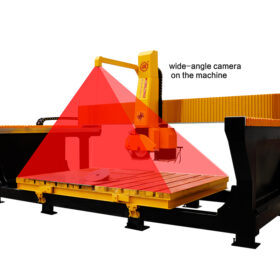

4 .Use wide-angle camera that occupy small the space (height)

5 .The whole slab image from desktop can be obtained by the camera and positioning at one time, which is intuitive to operate and eliminates manual positioning

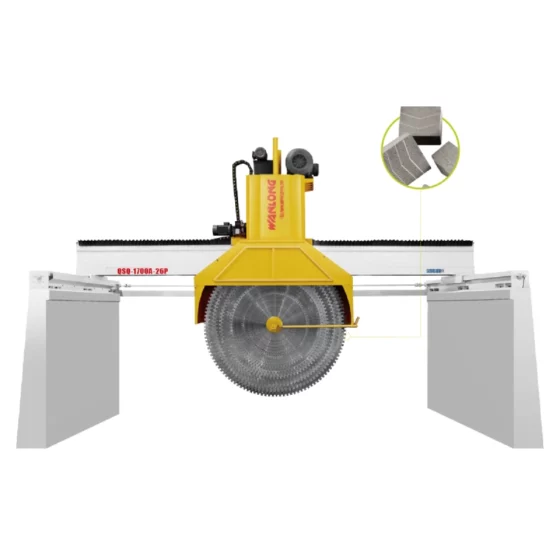

6 .Implement different complex curved surface processing, and combine the functions of cutting, miling, drilling, carving into an organic whole.

7. It supports RTCP, true 5-axis linkage, and can import the tool path processing software (自選) to generate G code to realize complex irregular processing

8. The configured AutoCAD plug-in can directly transfer the graphics to the five axis system in advance, which is easier to operate and supports the import of dxf files

9. The pneumatic control box is external for easy observation and adjustment

10. Linear slide rail and ball screw shall be selected from Taiwan HIWIN brand

11. Star gear reducer adopts Margtech

12. The robot reducer adopts Qinchuan brand

13. Pneumatic components shall be Taiwan Yadeke brand

|

型

|

單位

|

CNC-5 鉑金

|

|

線性軸行程(X-Y-Z)

|

毫米

|

3600-2460-300

|

|

C 軸行程

|

n°

|

±180

|

|

A 軸行程

|

n°

|

-1~91

|

|

葉片直徑

|

毫米

|

350-500

|

|

主電機功率

|

千瓦

|

18.5

|

|

主電機額定轉速

|

r/min

|

3600

|

|

Main motor highest rotation

|

r/min

|

6000

|

|

額定線速度 (X-Y-Z)

|

米/分鐘

|

30-30-6

|

|

主電機額定扭矩

|

nm

|

58.9

|

|

C 軸額定轉速

|

r/min

|

17.3

|

|

A 軸額定轉速

|

r/min

|

20.66

|

|

vacuum sunker numbers

|

4

|

|

|

麥克斯. capacity of vacuum sucker

|

公斤

|

360

|

|

rounter bit connector

|

ER25UM

|

|

|

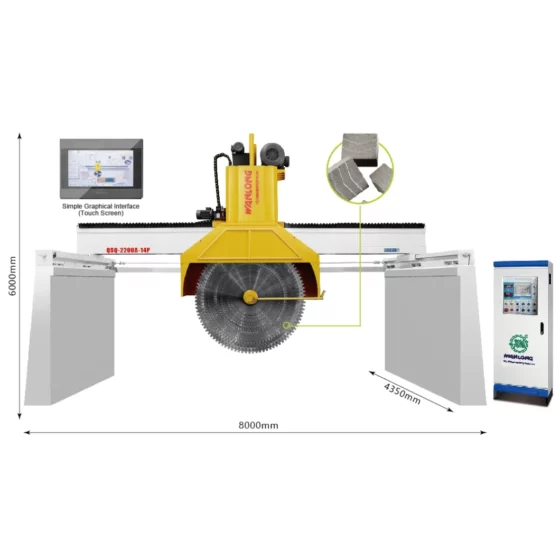

Table size

|

毫米

|

3200*2000(3500*2100)

|

|

Total power of machine

|

千瓦

|

31.2

|

|

Overall size

|

毫米

|

5850*3380*3050

|

|

Machine Weight

|

公斤

|

4000

|

|

耗水量

|

升/分鐘

|

15-25

|

|

Air consulmption

|

升/分鐘

|

176

|

切割案例

萬隆時代

萬隆時代