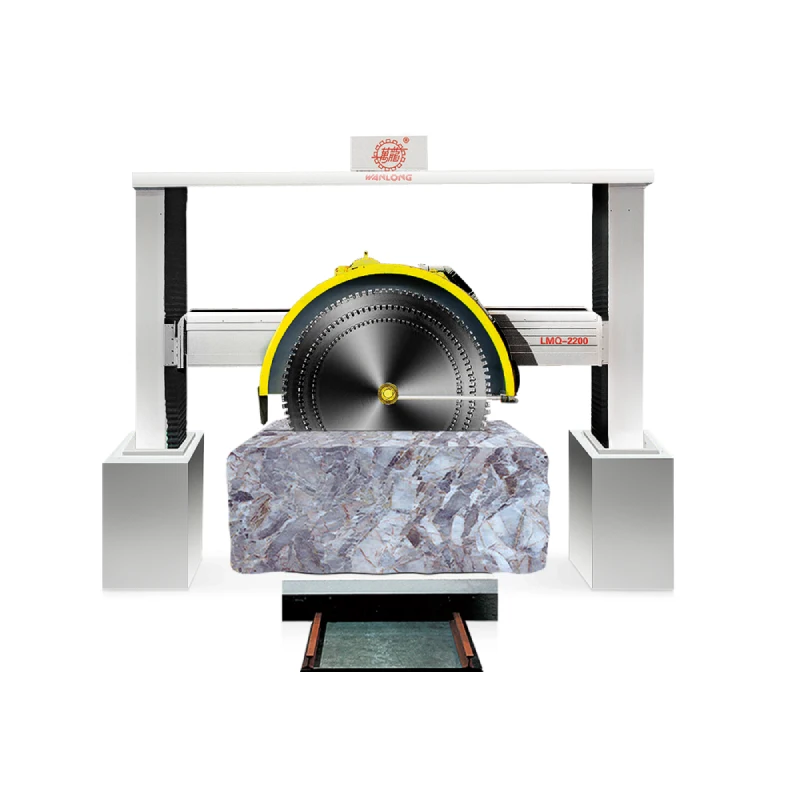

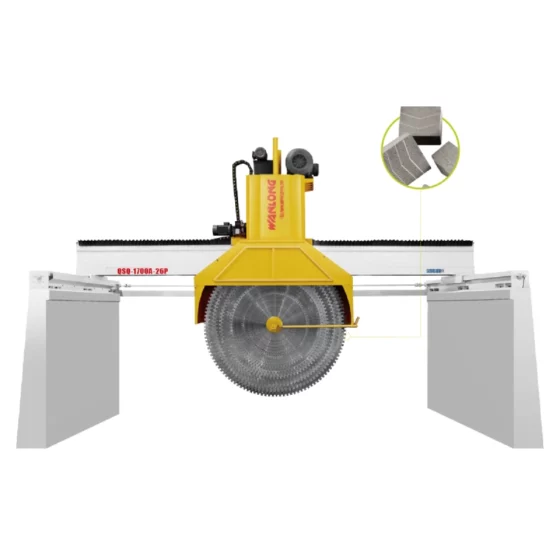

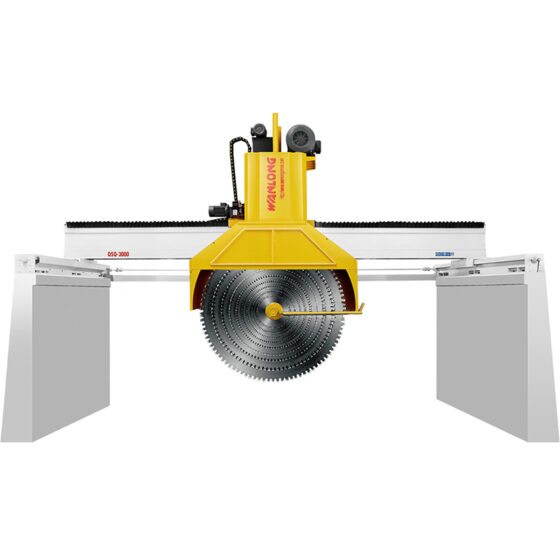

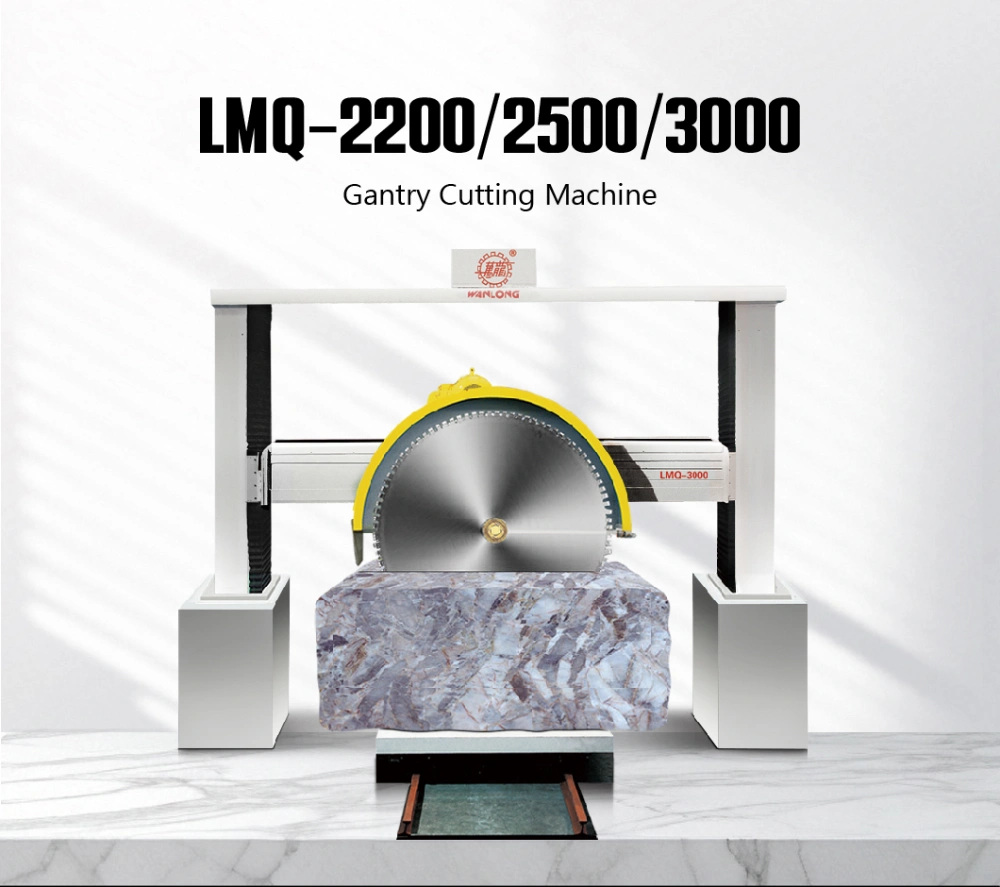

Gantry cutting machine consist of solid columns and wide-span crossbeam.It is specially for cutting large block into slabs,as its max cutting depth can reach 1350mm that large block processing is avaliable.It is suitable for prducing large scale slabs.Single Blade for Multi Blade working is avaliable.

Advantages of LMQ-2200/2500/3000 Gantry Cutting Machine:

1) Harden Screw Rod Guided for Blade Vertical Movement and for High Cutting Precision;

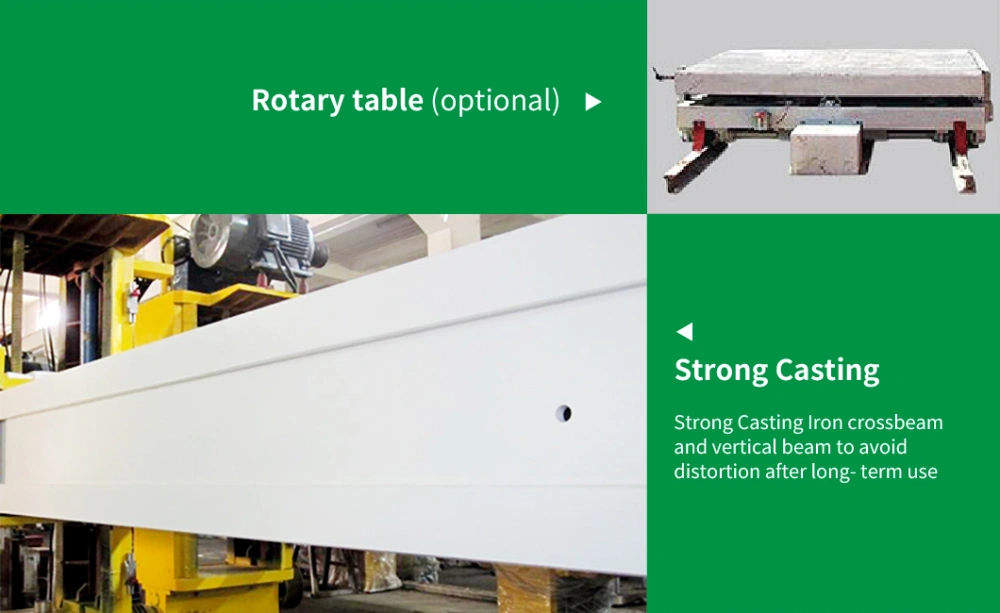

2) Gantry Structure with Cast Iron Crossbeam and Side Columns for durable working efficiency;

3) Great Cutting Capacity of 3400L x 2000W x 1350H but Small Area Taken for Machine Installation;

4) europeo & Componentes japoneses para prolongar la vida útil de la máquina, Precisión de trabajo y fácil de operar & Mantener;

5) Block Movement Driven by Standard Single-Layer Trolley and Double-Layer Rotable Trolley upon Customer Request.

LMQ-2200/2500/3000 Gantry Cutting Machine for granite,marble block

Características

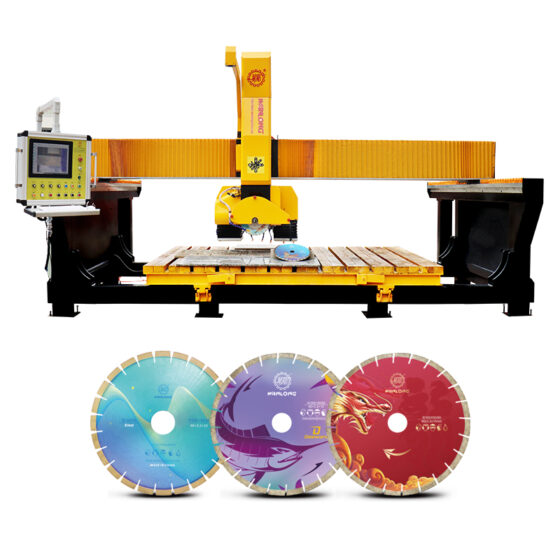

1. Single blade or Multiblade combination working is avaliable ,which need to inform while placing order.

2. Fully-controlled by microcomputer,it can work automatically by programmed.Or work manual to meet the flexibility.

3. Heavy casting iron ,strong

4. It work with motorized table for feeding the block.

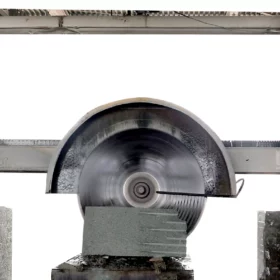

5. Its liner speed is 43 meters/second .Very high efficiency.

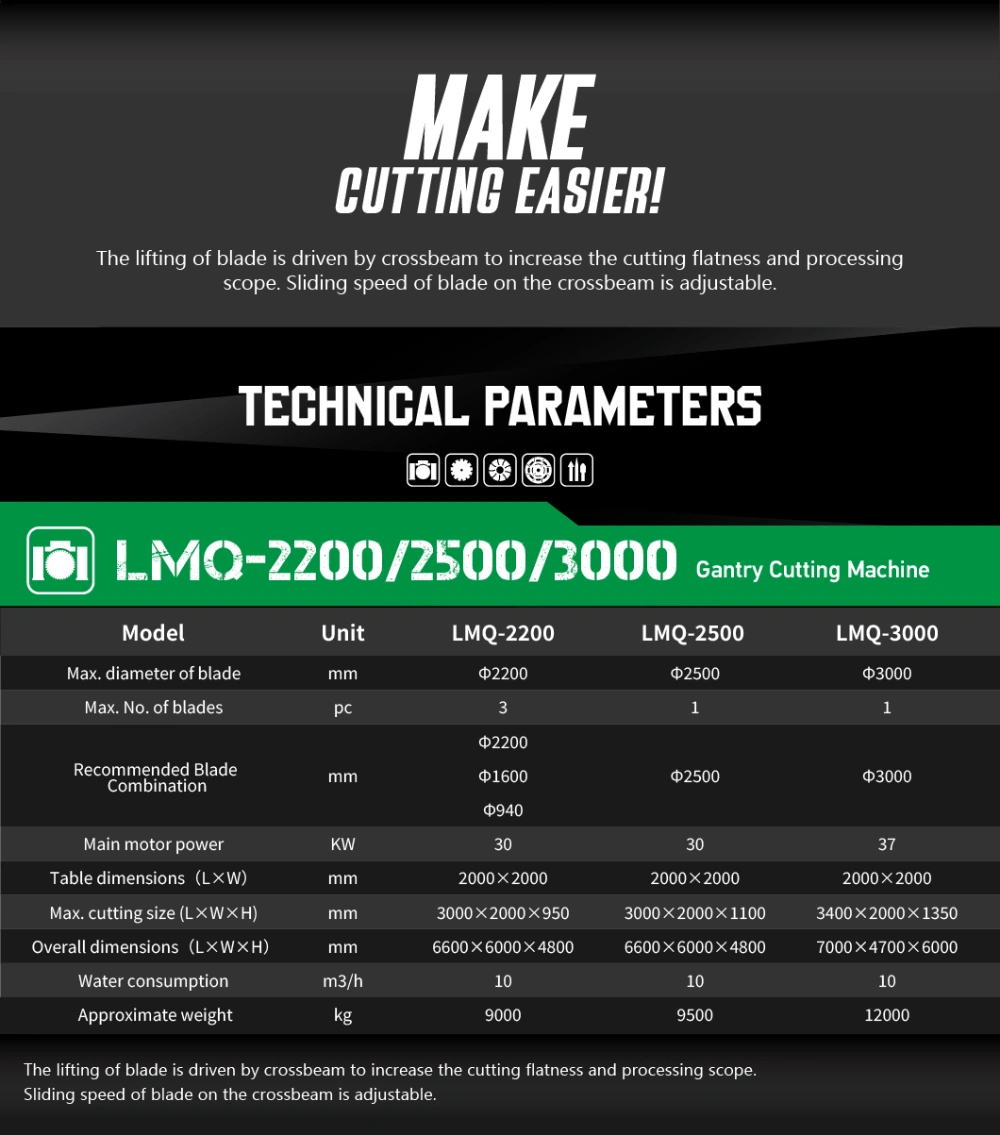

| Modelo | Unidad | LMQ-2200 | LMQ-2500 | LMQ-3000 |

| Máximo. Diámetro de la hoja | mm | 2200 | 2500 | 3000 |

| Máximo. No. de cuchillas | pieza | 3 | 1 | 1 |

| Combinación de hoja recomendada | mm | φ2200 φ1600 φ940 | φ2500 | φ3000 |

| Potencia del motor principal | kilovatios | 30 | 30 | 37 |

| Dimensiones de la mesa ( Largo x Ancho ) | mm | 2000*2000 | 2000*2000 | 2000*2000 |

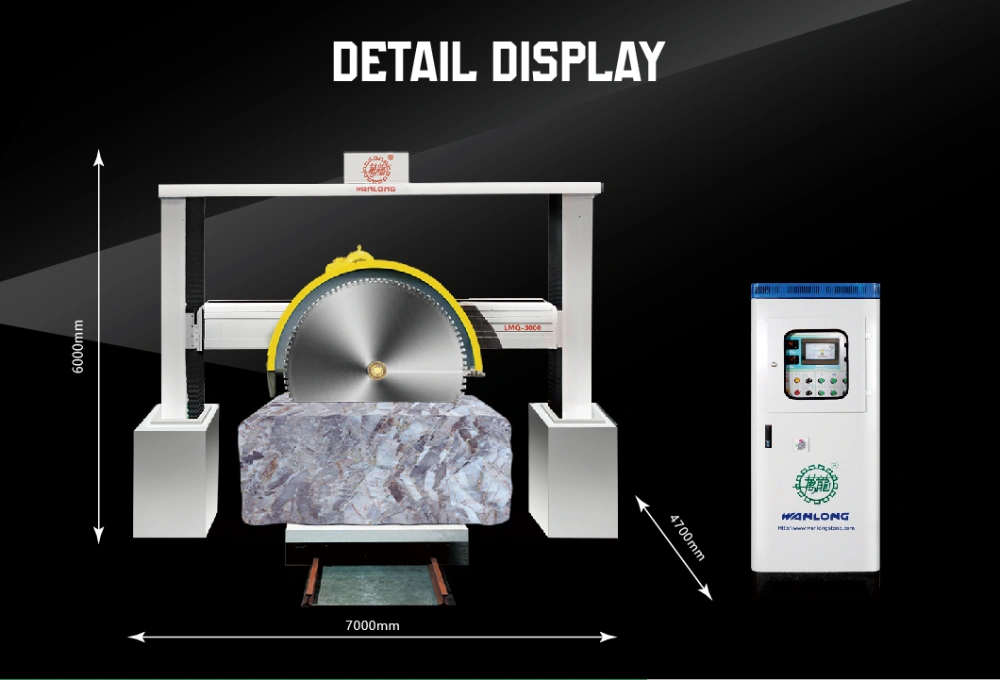

| Máximo. Tamaño de corte (Largo x Ancho x Alto) | mm | 3000*2000*950 | 3000*2000*1100 | 3400*2000*1350 |

| Dimensiones totales ( Largo x Ancho x Alto ) | mm | 6600*6000*4800 | 6600*6000*4800 | 7000*4700*6000 |

| Consumo de agua | m3/h | 10 | 10 | 10 |

| Peso aproximado | Kg | 9000 | 9500 | 12000 |

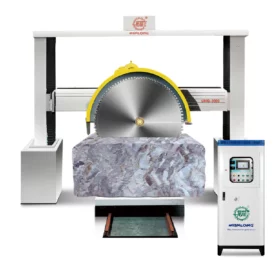

Main Configuration:

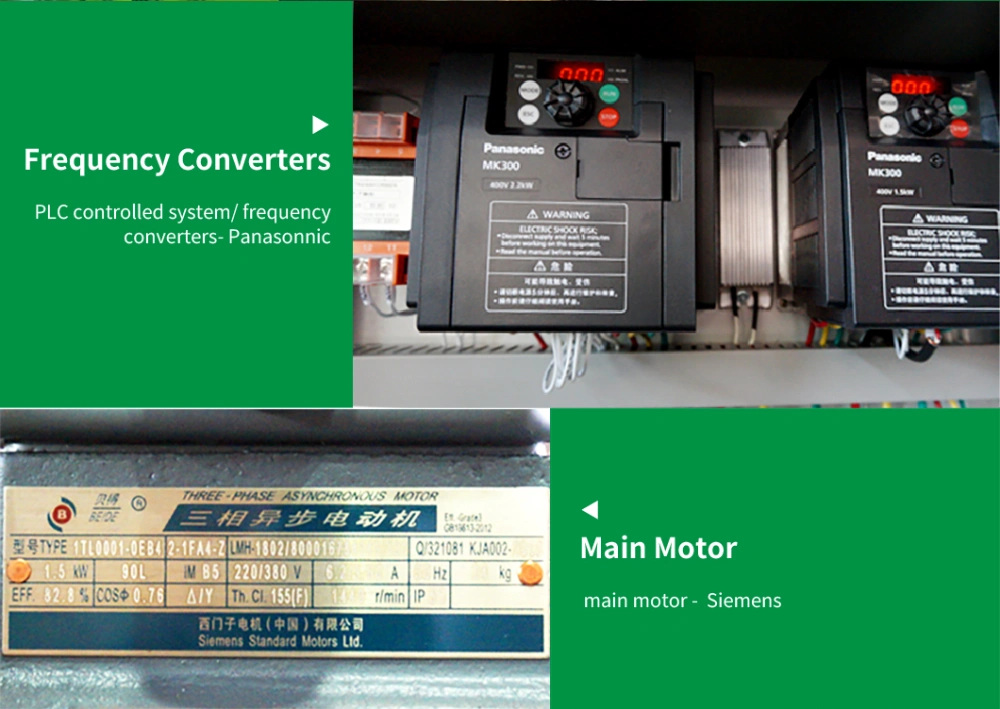

1. Motor principal SIEMENS con asientos más resistentes.

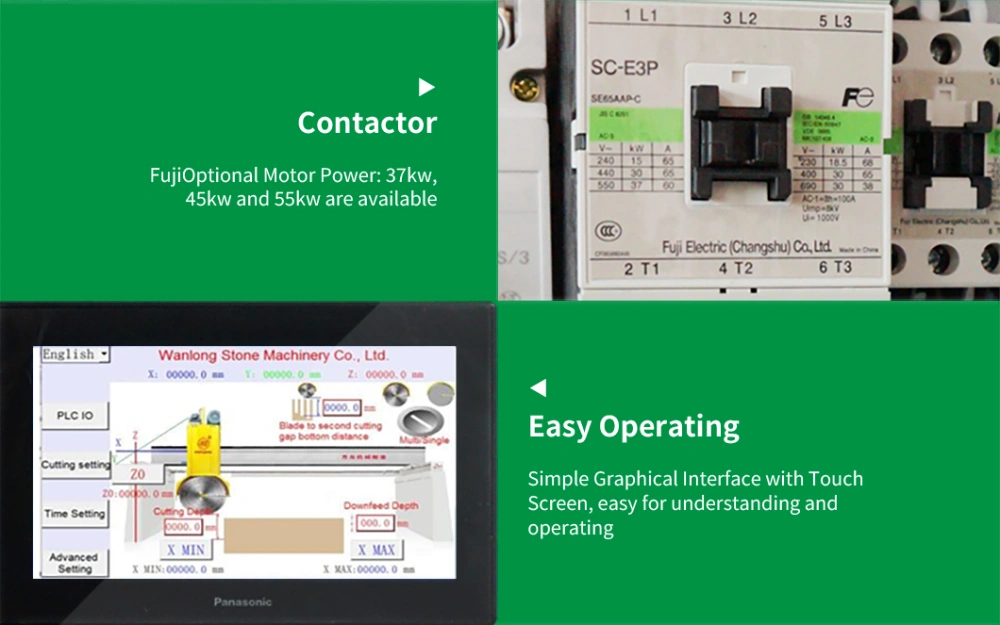

2. PLC e inversor PANASONIC.

3. FuJI contactor.

4. Hierro fundido resistente HT200.

5. Panel sensible al tacto Fácil de operar para el trabajador.

6. 40-48m² por 10 horas para granito de dureza media.

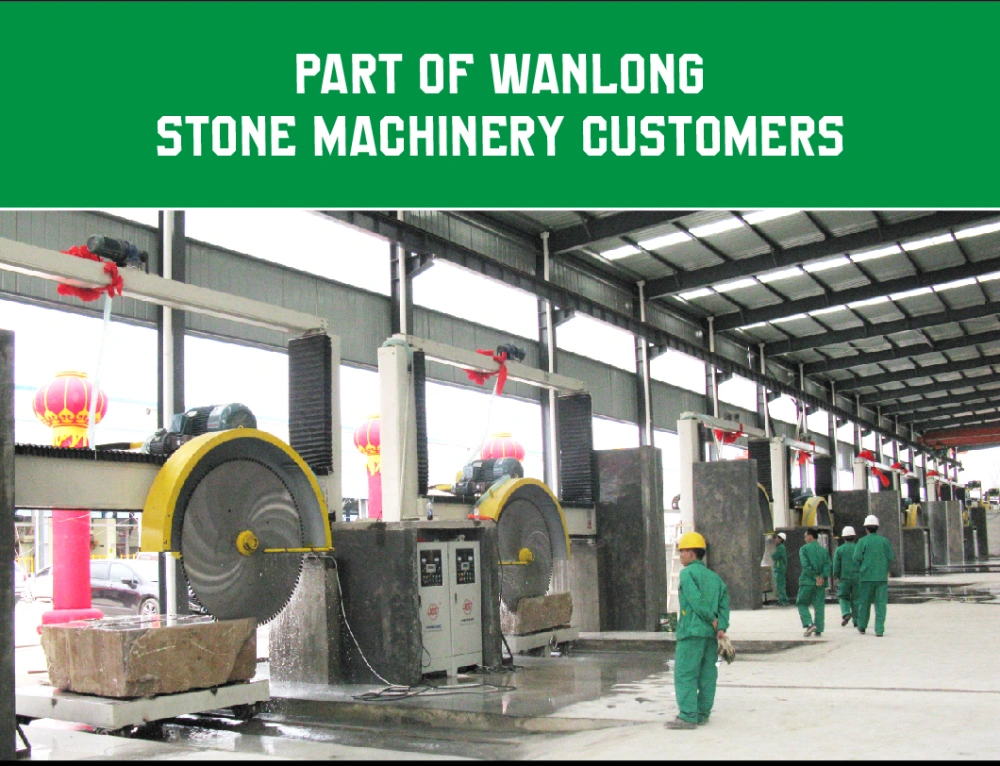

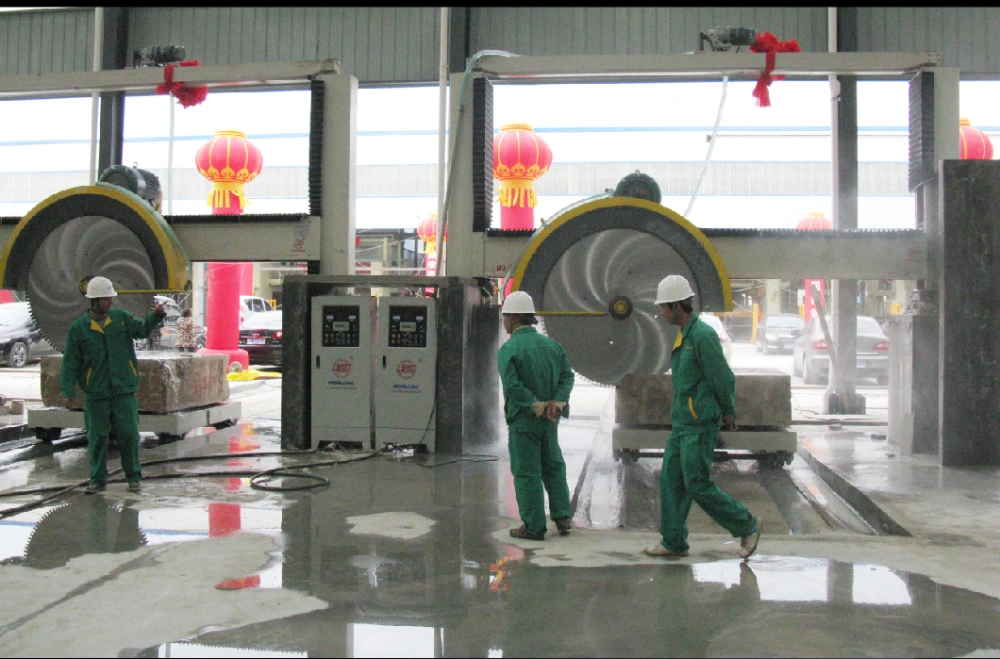

TIEMPOS DE WANLONG

TIEMPOS DE WANLONG